BIONICS ENVIRO TECH is an industry world leader in the field of biological waste water treatment by manufacturing Nanozyme Bioculture and implementing it in all industries. With presence in all states, BIONICS ENVIRO TECH with strong Research & Development and a passion for innovation is offering purely Nanozyme technologies with wide range of solutions mainly focused on COD, BOD Reduction, Zero Sludge Process, Zero Pollutant load in directed at addressing wastewater challenges in all industries Effluent Treatment Plants Treatment Plants (CETP) and Anaerobic Digester (AD) of any scale, any sector across the world with track record.

“NANOZYME” which are effective microbes (EM) contain multiple stains of aerobic, facultative aerobes and anaerobic bacteria, which are selected for their compatible, symbiotic metabolic pathways based on different industrial effluent characteristics. NANOZYME products are manufactured from a unique solid fermentation (SSF) process of selected cultures of beneficial bacteria for different waste water and industries.

Under our Executive Director Dr. M. PARAMESWARI SASIKUMAR, Executive Director – Ph.D., in Agricultural Science with specialization in Industrial Wastewater treatment research guidance, BIONICS ENVIRO TECH has innovating wide range of NANOZYME bio-culture and also implementing into various all industrial sectors.

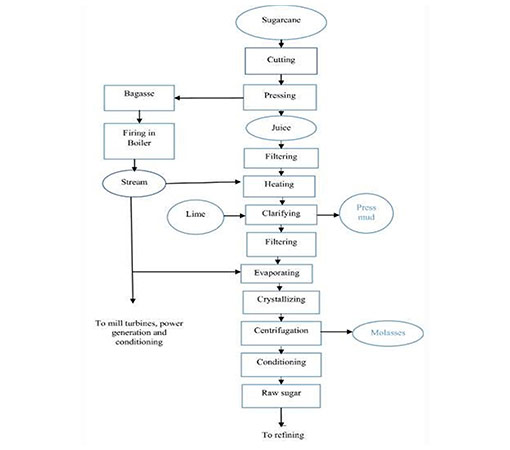

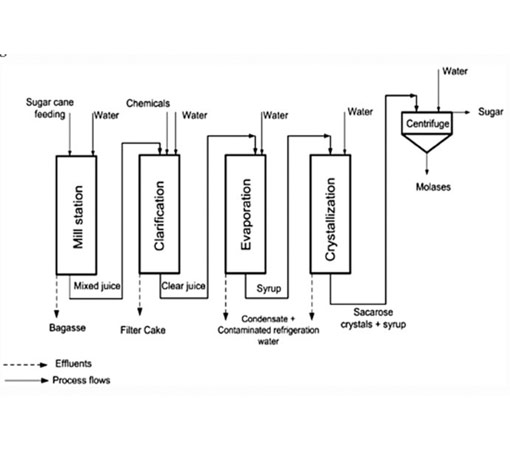

Sugarcane is known to be one of the oldest cultivated plants in tropical and subtropical countries. Sugar industries are increasing exponentially to satisfy the growing demand for sugar; whereas, the ethanol distilleries have been rapidly expanding, since bioethanol emerged as an affordable, low carbon footprint and renewable bioenergy. However, inadequately treated and indiscriminate disposal of the effluent from sugarcane industries resulted in extensive soil and water pollutions. Hence, Bionics Enviro Tech study aimed at reviewing the sugarcane industrial process with its water consumption rates, and effluent characteristics and its adverse effects on the environment.

Bionics Enviro Tech has gone through the most common wastewater treatment efforts made to minimize the effluent environmental burden. In addition to the large volumes of sugar and ethanol industrial effluents, the presence of the different varieties of the pollutants in the effluent is challenging for conventional treatment methods. However, eliminating the pollutants is becoming important for environmental and esthetic values. However, Aerobic & Anaerobic digestion of high rate was found in the state of the art and an effective approach to treat the sugar industry and ethanol distillery effluents.

ABOUT BIONICS

BIONICS ENVIRO TECH is an industry world leader in the field of biological waste water treatment by manufacturing Nanozyme Bio-culture and implementing it in all industries. With presence in all states, BIONICS ENVIRO TECH with strong Research & Development and a passion for innovation is offering purely Nanozyme technologies with wide range of solutions mainly focused on COD, BOD Reduction, Zero Sludge Process, Zero Pollutant load in directed at addressing wastewater challenges in all industries Effluent Treatment Plants Treatment Plants (CETP) and Anaerobic Digester (AD) of any scale, any sector across the world with track record.

ABOUT NANOZYME

“NANOZYME” which are effective microbes (EM) contain multiple stains of aerobic, facultative aerobes and anaerobic bacteria, which are selected for their compatible, symbiotic metabolic pathways based on different industrial effluent characteristics. NANOZYME products are manufactured from a unique solid fermentation (SSF) process of selected cultures of beneficial bacteria for different waste water and industries.

NANOZYME ANAEROBIC DIGESTION

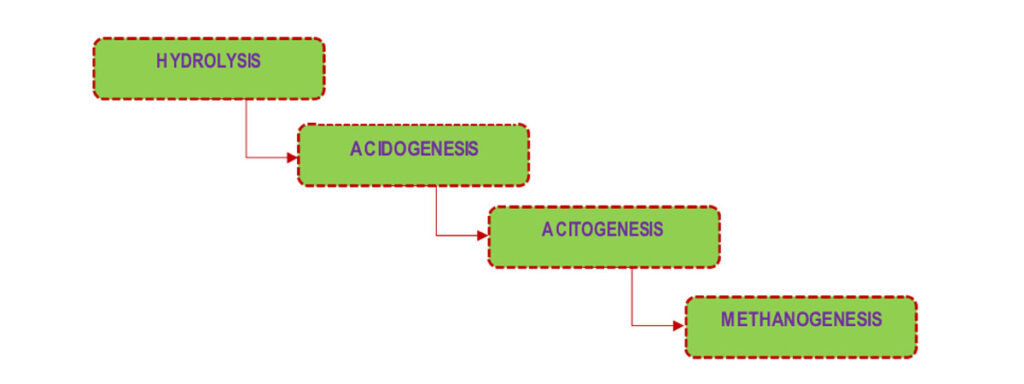

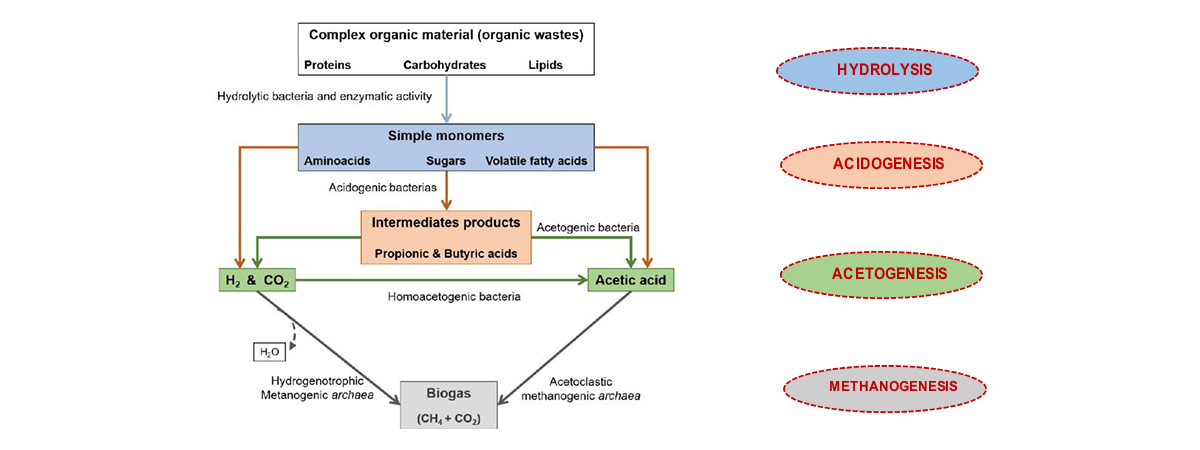

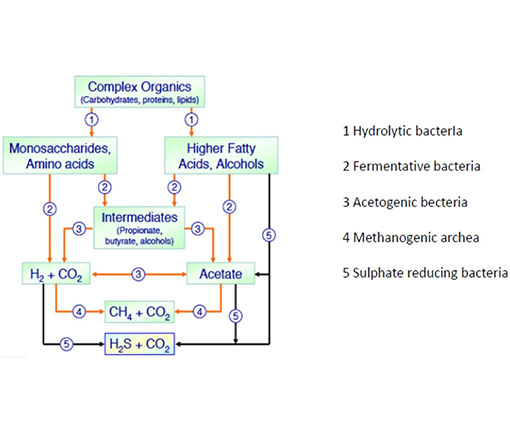

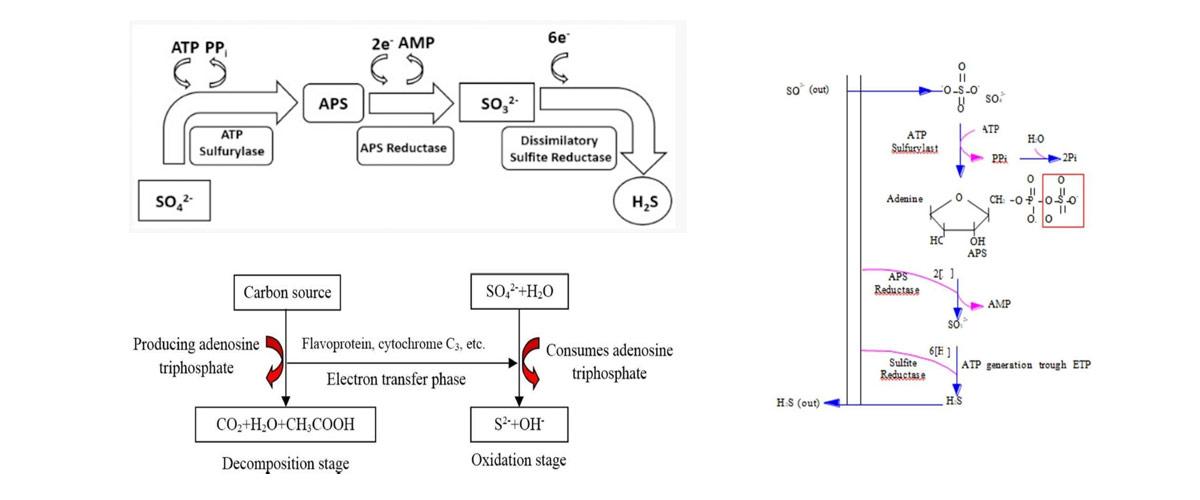

Anaerobic digestion is a sequence of processes by which NANOZYME MICROBIAL CULTURE break down biodegradable material in the absence of oxygen. The process is used for industrial purposes to produce fuels. The digestion process begins with NANOZYME MICROBIAL hydrolysis of the input materials. Insoluble organic polymers, such as carbohydrates, are broken down to soluble derivatives that become available for other bacteria. Acidogenic Nanozyme bacteria then convert the sugars and amino acids into carbon dioxide, hydrogen, ammonia, and organic acids. In acetogenesis, NANOZYME bacteria convert these resulting organic acids into acetic acid, along with additional ammonia, hydrogen, and carbon dioxide amongst other compounds. Finally, methanogens convert these products to methane and carbon dioxide. Nanozyme methanogenic archaea consortia populations play an indispensable role in anaerobic wastewater treatments.

NANOZYME TECHNOLOGY have four stages of digestion pathways for anaerobic digestion as below

The four key stages of anaerobic digestion involve hydrolysis, acidogenesis, acetogenesis and methanogenesis. The overall process can be described by the chemical reaction, where organic material such as glucose is biochemically digested into carbon dioxide (CO2) and methane (CH4) by the anaerobic microorganisms.

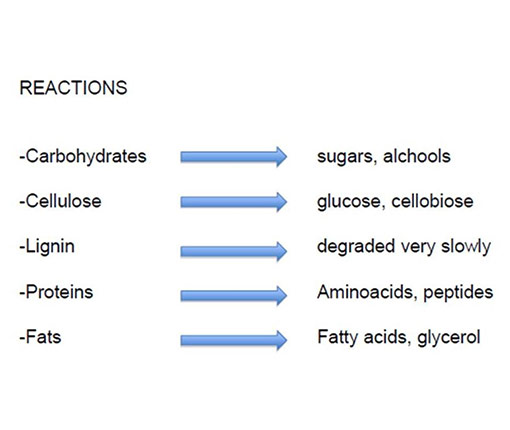

HYDROLYSIS

NANOZYME microbial culture applied in anaerobic digesters to access the energy potential of the material, these complex chains must first be broken down into their smaller constituent parts. These constituent parts, or monomers, such as sugars, are readily available to NANOZYME consortia. The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis. Hydrolysis of these high-molecular-weight polymeric components is the necessary first step in NANOZYME anaerobic digestion. Through hydrolysis the complex organic molecules are broken down into simple sugars, amino acids, and fatty acids.

Acetate and hydrogen produced in the first stages can be used directly by methanogens. Other molecules, such as volatile fatty acids (VFAs) with a chain length greater than that of acetate must first be catabolised into compounds that can be directly used by methanogens.

ACIDOGENESIS

NANOZYME biological process of acidogenesis results in further breakdown of the remaining components by acidogenic (fermentative) NANOZYME bacteria. Here, VFAs are created, along with ammonia, carbon dioxide, and hydrogen sulfide, as well as other by products. The process of acidogenesis is similar to the way milk sours.

ACETOGENESIS

The third stage of anaerobic digestion by NANOZYME technology is acetogenesis. Here, simple molecules created through the acidogenesis phase are further digested by acetogens to produce largely acetic acid, as well as carbon dioxide and hydrogen.

METHANOGENESIS

The terminal stage of anaerobic Nanozyme digestion is the biological process of methanogenesis. Here, methanogens use the intermediate products of the preceding stages and convert them into methane, carbon dioxide, and water. These components make up the majority of the biogas emitted from the system. Methanogenesis is sensitive to both high and low pHs and occurs between pH 6.5 and pH 8. The remaining, indigestible material the microbes cannot use and any dead bacterial remains constitute the digestate.

In aerobic respiration, organic matter such as glucose is oxidized to CO2, and O2 is reduced to H2O. In contrast, during hydrogenotrophic methanogenesis, H2 is oxidized to H+, and CO2 is reduced to CH4

Methyl-coenzyme M reductase MCR, coenzyme B sulfoethylthiotransferase is the final enzyme involved in methanogenesis (methane biogenesis).

Molasses is the more important by-product and it is used as carbon source in fermentations, biofertilizer and feed for domestic animal. Molasses is commonly used as raw material in fermentation industries, especially for ethanol production because of its low-cost, availability and suitability for fermentation process.

Molasses Content:

1 MT of Sugarcane – 4% of Molasses Total Solids : 75 to 85%

Sucrose : 30 to 36%

Fructose + Glucose : 10 to 16% Fermentable sugar : Approx. 50%

Some smaller Quantities of Polysaccharides, Oligosaccharides, Organic Acids, Proteins & Nitrogen compounds

Alcoholic fermentation is a biotechnological process accomplished by NANO- FERMENTOZYME [BIONICS-NANO-FERM-10] to convert sugars into ethyl alcohol and carbon dioxide.

In this fermentation process, NANO-FERMENTOZYME [BIONICS-NANO-FERM-10] is used as a bio-culture and aqueous solution of monosaccharide (raw materials) as the culture media for the production of beverages.

In the alcoholic fermentation process, NANO-FERMENTOZYME [BIONICS-NANO-FERM-10] generally carries out the aerobic fermentation process, but it may also ferment the raw materials under anaerobic conditions. In the absence of oxygen, alcoholic fermentation occurs in the cytosol of Nanozyme.

Alcoholic fermentation begins with the breakdown of sugars by NANO-FERMENTOZYME [BIONICS-NANO-FERM-10] to form pyruvate molecules, which is also known as glycolysis. Glycolysis of a glucose molecule produces two molecules of pyruvic acid. The two molecules of pyruvic acid are then reduced to two molecules of ethanol and 2CO2

Under anaerobic conditions, the pyruvate can be transformed to ethanol, where it first converts into a midway molecule called acetaldehyde, which further releases carbon dioxide, and acetaldehyde is converted into ethanol.

FERMENTATION: BIONICS-NANO-FERM-10 ( BIONICS – MAKE)

NANO-FERMENTOZYME are specifically formulated for Indian climate to be used as an alcohol yield booster in molasses fermentation plants. Our NANO-FERMENTO ZYME are 100% eco-friendly, safe for usage and offered in air-tight packaging at cost effective rates.

NANO-FERMENTO ZYME (BIONICS MAKE) is a Consortia of bio-enzyme with organic nutrients The organic nutrients facilitate faster yeast propagation by providing the essential micro & macro elements for the yeast growth enzymes breakdown the higher saccharides and proteins occurring naturally in the molasses making them available for fermentation the anti-microbial components reduce microbial contamination in the fermentation system the cumulative result of these three actions results in increased alcohol yield in molasses fermentation.

S.No. | MERITS OF NANO-FERMENTO ZYME (BIONICS MAKE) |

1. | · Increase in overall yield with alcohol percentage. · Increase the production and productivity of the plant. · Reduction of other contamination. · Reduction in overall operation cost. · Avoid the chemicals for fermentation and Completely eliminate the usage of Urea & DAP. · Significant Reduction of total fermentation time. · Efficient & easy for handling the fermentation system |

2. | PROPERTIES OF NANO-FERMENTOZYME (BIONICS MAKE) |

| · Colour: Light Wheaties yellow Powder · Operating PH: 2 to.12 PH · Dosage: Recommended dosage is 1 kg./100KLD/Day of the fermentation wash. However the exact dosage may vary and need to be optimized. · Molasses water ratio in the wash. · Operating temperature and PH. · Packing: NANO-FERMENTOZYME is available in standard 25 kgs and 50 Kgs HDPE drum. |

Fermentation refers to the metabolic process by which organic molecules (normally glucose) are converted into acids, gases, or alcohol in the absence of oxygen or any electron transport chain.

Fermentation pathways regenerate the coenzyme nicotinamide adenine dinucleotide (NAD+), which is used in glycolysis to release energy in the form of adenosine triphosphate (ATP).

The overall chemical formula for alcoholic fermentation is:

GLUCOSE → 2 ETHANOL + 2 CARBON DIOXIDE

C6H12O6 → 2 C2H5OH + 2 CO2

| Parameter | Distillery Unit |

|---|---|

| Temperature (°C) | 46.3–56.3 |

| pH | 3.9–4.9 |

| Electric conductivity (µS/cm) | 3910.0–50,500.0 |

| BOD5 | 50,000.0–60,000.0 ppm |

| COD | 110,000 –190,000 ppm |

| Chloride | 6213.6–7475.7 |

| Total hardness | 3100.3–4, 477.2 |

| Calcium | 2676.5–3389.8 |

| Magnesium | 816.3– 1828.1 |

| Total solid | 91,876.9–150,300.9 |

| Total dissolved solids | 13,000.0–88,265.1 |

| Total suspended solids | 3611.1–150,000.0 |

| Nitrates | 2.40.3–32.9 |

| Organic —N | 75.2—400.7 |

| Ammonia —N | 10.9—18.1 |

| Total nitrogen | 85.8—1355.3 |

| Phosphate | 1.2—27.6 |

| Sulphate | 803.0—6050.5 |

| Oil greases | 30.3—202.1 |

| Values of distillery effluent | Values of distillery effluent | Anaerobically treated effluent quality |

|---|---|---|

| pH | 3.0—4.5 | 7.5—8.0 |

| BODs | 50,000—60,000 | 8000—10,000 |

| COD | 110,000—190,000 | 45,000—52,000 |

| Total solids | 110,000—190,000 | 70,000—75,000 |

| Total volatile solids | 80,000—120,000 | 68,000—70,000 |

| Total suspended solids | 13,000—15,000 | 38,000—42,000 |

| Total dissolved solids | 90,000—150,000 | 30,000—32,000 |

| Chloride | 8000—8500 | 7000—9000 |

| Phenols | 8000—10,000 | 7000—8000 |

| Sulphate | 7500—9000 | 3000—S000 |

| Phosphate | 2500—2700 | 1500—1700 |

| Total nitrogen | 5000—7000 | 4000—4200 |

Ethanol distillery is the highest consumer of raw water (25—175 L/L of alcohol) for non-process applications, like cooling water, steam generation, etc. and the process consumption such as yeast propagation, molasses preparation.

The major sources of wastewater in molasses-based distilleries are

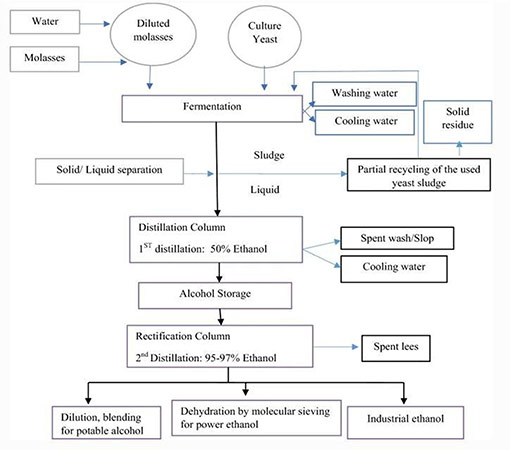

Fermented wash is the main product of fermentation which is decanted; the remaining sludge is known as yeast sludge (fermenter sludge). This discharged effluent from the bottom of the fermenters contributes to the pollution load from the distilleries. Hence, the fermenter sludge is the wastewater generated after fermentation, which is separated from the ethanol solution by filtration. However, spent lees are the residue obtained from rectifier column which are usually recycled. Normally, spent lees are hot and colourless liquid at the generation rate of 1.7—2.0 L/L of rectified spirit. Among these wastewater categories, spent wash is the major wastewater of the ethanol distillery, both in terms of quality and quantity, and is referred to as vinasse, stillage, slop or molasses spent wash. Practically in the distillery, the spent wash production rates and characteristics are highly variable depending on the type of feedstock (quality of molasses), fermentation technique, and unit operation in molasses processing and ethanol recovery process. These factors are the major contributors to the pollution load of the distillery effluent. Generally, spent wash is the main source of wastewater in distillation process which is subjected to treatment.

Distillery spent wash is the most complex and troublesome effluent having strongest organic matter in terms of high COD (80,000–160,000 mg/L), high temperature, high ash content, low acidity (pH 3.7–4.5) with a high content of dissolved inorganic salts Hence, this molasses spent wash is one of the most difficult waste products to dispose because the pollutants are environmentally not compatible. In addition to high organic matter contents, another peculiar feature of the spent wash is its deep dark brown colour which resulted from the colour causing pigments. Furthermore, the colorant of spent wash is mainly caused by melanoidins (from Maillard reaction of sugars (carbohydrates) with the protein amino groups), caramels (from overheated sugars—caramelized), phenolic (from tannic and humic acids of the feedstock), and furfurals (from acid hydrolysis). Specifically, the caramelization is the chemical reaction process of sugars at high temperatures, which can be catalysed by the acid and base solution. Generally, this colour-bearing distillery wastewater is a challenge to treat.

Among the colour causing pigments, melanoidins (C17–18H26–27O10N) are the major cause for the dark brown colour of the spent wash which is formed under non-enzymatic (Maillard) reaction between sugar and amino compounds at high temperature. Melanoidin is described by its unique nature such as the recalcitrant, antioxidant, acidic, nitrogen containing dark brown polymeric compound. Normally, molasses-based ethanol distillery spent wash is the major source of melanoidins wastewater source. The estimated molecular weight of melanoidins is to be between about 5000 and 40,000 Da and accounts for 2% of the total spent wash by mass . Additional properties of the melanoidins are very negatively charged long polymer of acidic compound with colloidal properties due to the dissociation of carboxylic acids and phenolic groups. The molasses distillery wastewater has similarities with sugar industry wastewater in composition, but the distillery spent wash is a high strength wastewater. Comparative analysis of the physicochemical quality of the sugar industry and distillery effluents was conducted under similar condition which showed clearly the difference in concentrations strength as indicated in Table.

An enzyme is a globular protein with an active site which bind to substrate molecules and helps to catalyse a reaction by holding molecules in the correct spatial conformation for the reaction to take place. The activities of the enzymes are determined by their 3-dimensional structure. Most enzymes are much larger than the substrates they act on and only a small portion of the enzyme around 3-4 amino acids is directly involved in catalysis.

Nanozyme are based on the latest advanced technology in biotechnology designed to meet the requirements of specific waste water treatment problems. Biological treatment method by Nanozyme microbes is the only method that can eliminate/degrade the waste problem. Specially selected and acclimated strains of microorganisms supplied in NANOZYME microbial enzyme products produce millions of times the levels of organic digesting catalysts produced by various type of microorganisms found naturally in different waste. Bacteria are living organisms that continually adapt and grow in the system.

Nanozyme Effective Microorganism (EM) is the consortia of valuable microorganisms which secretes organic acids and enzymes for utilization and degradation of anthropogenic compounds. Combination of various strains will successively promotes the growth of bacterial population, break down and digest the waste in both aerobic and anaerobic conditions to a far greater degree than single microbial strain. Bioremediation process involves detoxification and mineralization, where the waste is converted into inorganic compounds such as carbon dioxide, water and methane. When compounds are persistent in the environment, their biodegradation often proceeds through multiple steps utilizing different enzyme systems or different microbial populations.

Nanozyme Bacterial digestion is the process of bacteria, consuming organic & Inorganic matter. Enzymes act to break the organic & Inorganic matter into water soluble nutrients, which the bacteria digest. Using complex chemical reactions, the organic & Inorganic waste is metabolized down to water and carbon dioxide (the final metabolic waste products), providing the bacteria with energy for growth and reproduction. It may be simply shown by the following equation

Organic waste + Water Soluble Nutrients —–Bacteria + oxygen—> water + carbon dioxide

Organic waste + Water ——Enzyme—-> Water Soluble Nutrients —–Bacteria—> WATER + CARBON DIOXIDE + METHANE

We are using our product nanozyme in aeration tank capacity which means the ammonical nitrogen totally converted into nitrate nitrogen. It’s an available intake form to our bacteria. So totally we can eliminate the odour and control the ammonical nitrogen odour is because of ammonical and hydrogen sulphide.

No need to remove condensate.

Note that a total ammonia value (NH3 + NH4) cannot be trivially converted from “nitrogen” to “ion” form or vice versa. The total ammonia value must first be broken into component NH3 and NH4 values, then converted individually to NH3-N and NH4-N and added together.

Ammonia removal is a strictly aerobic biological process. Technically, bacteria convert ammonia (NH4 ) to nitrate (NO3 ); it isn’t really “removed.” Nitrification only works on ammonia (NH4 ). Organic-nitrogen is not converted directly to nitrate (NO3 ); it must first be converted to ammonia (NH4 ), and the ammonia (NH4 ) converted to nitrite (NO2 ) and then nitrate (NO3 ).

Organic / Inorganic pollutant load is consumed by the bacteria, used as nutrients by the bacteria, and is no longer present to produce odours, sludge, pollution, or unsightly mess.

The removal of pollutants from the Effluent by using NANOZYME (Effective Microbes (EM)- bacterial consortium manufactured in BIONICS ENVIRO TECH having potential to degrade all organic and inorganic compounds present in the Effluent.

When degradation Organic and inorganic take place which will automatically lead to reduction of COD, When COD takes places which will reflect BOD, Colour, smell and etc parameters.

CAPACITY : 5.4 MLD

| S.NO | PRODUCT DESCRIPTION | UNIT |

|---|---|---|

| 1 | BIONICS NANO-DIST-ANA-2000 | KGS |

| 2 | BIONICS NANO-FERM-1000 | KGS |

| COMPANY NAME | AREA | APPLICATION |

|---|---|---|

| SUGAR ETP | ||

| KM SUGAR | AYODHYA, UTTAR PRADESH | CPU-ETP |

| SULPHATE REMOVAL | ||

| SUGAR ETP | ||

| RANA SUGAR | AMRITSTAR, PUNJAB | CPU-ETP |

| SUGAR ETP | ||

| CPU-ETP | ||

| FERMENTATION BOOSTER | ||

| JAI BHAVANI SSK LTD | MAHARASTRA BEED | COMPOSTING |

| SIDDHI SUGAR & ALLIED INDUSTRIES LTD | MAHARASTRA, LATTUR | SUGAR ETP |

| CPU-ETP | ||

| JARANDESHWAR SUGAR MILLS PVT LTD | MAHARASTRA, SATTARA | SUGAR ETP |

| CPU-ETP | ||

| KARMAVEER SHANKARRAO KALE SSK LTD | MAHARASTRA, AHMEDNAGAR | SUGAR ETP |

| CPU-ETP | ||

| BARMATI AGRO LTD | PUNE, MAHARASTRA | SUGAR ETP, |

| ANAEROBIC | ||

| JAKARYA SUGAR | SOLAPUR, MAHARASTRA | SUGAR ETP |

| CPU-ETP | ||

| THE SASWAD MALI SUGAR | SOLAPUR, MAHARASTRA | SUGAR ETP |

| CPU-ETP | ||

| KAPEESHWAR SUGARS & CHEMICALS LTD | MAHARASTRA, HINGOLI | SUGAR ETP |

| CPU-ETP | ||

| NATURAL SUGAR & ALLIED INDUSTRIES | PUNE, MAHARASTRA | SUGAR ETP |

| CPU-ETP | ||

| THE AMARAVATHI CO-OPERATIVE SUGAR | UDUMALAIPET, TAMILNADU | BIO GAS GENERATION |

| DHARASHIV SUGAR | NASHIK, MAHARASTRA | SUGAR ETP |

| CPU-ETP | ||

| SITARAM MAHARAJ SUGAR | SOLAPUR, MAHARASTRA | SUGAR ETP |

| CPU-ETP |

REQUIRED MATERIALS FOR PREPARATION: FERMENTATION

NANOZYME INCUBATION METHOD:

Recommended dosage is 500 kgs of Nanozyme per

| Dosage | Day of Dosage | From 5000 litres of prepared broth Volume of Nanozyme Application to Aeration |

|---|---|---|

| 1st Dosage | 1st to 10 days | 150 Litres / Day |

| 2nd Dosage | 11th to 20th Days | 150 Litres / Day |

| 3rd Dosage | 21st to 30th Days | 150 Litres / Day |

| S.no | Product Description | Unit | Qty | Unit Price in INR |

|---|---|---|---|---|

| 1 | BIONICS NANO-DIST-ANA-2000 | Kgs | 500 | 1200 |

| 2 | BIONICS NANO-FERM-1000 | Kgs | 200 | 1300 |

Offer Validity : 30 Days from the date of Proposal

Delivery : Immediate, Ex stock Subject to prior sale

Freight : To Pay by SAYAN

Shelf Life : Minimum One year

Payment Terms : 50% Advance Along with Order Balance Against Delivery at Site

Bank Details : BANK NAME: ICICI BANK

BRANCH: ERODE PAARI NAGAR

ACCOUNT NAME: Bionics Enviro Tech Private Limited,

ACCOUNT TYPE: Current- Account

A/C Number: 155205002872, IFSC CODE: ICIC0001552