Anaerobic Microbial Culture

Product Details

| Available Form | Organic Semi-Solid Form |

| Number of Bacterial Cultures | 45 Different Bacterial Cultures |

| Stage of Bacterial Cultures | Living Bacteria |

| Number of Bacterial Colonies | 21 x 10-9 CFU/ml |

| Shelf Life | Min One Year |

Effluent Parameter Reduction Chart

| Parameters | Percentage of Reduction |

| Sludge Degradation | Zero Sludge |

| Chemical Oxygen Demand ( COD ) | 90 – 98 % |

| Biological Oxygen Demand ( BOD ) | 98 – 100 % |

| Colour | 90 – 100 % |

| Odor | 100 % |

| Removal of Suspended & Floatable Organic Debris | 100 % |

| Reduces Total Suspended Solids ( TSS ) | 95 – 98 % |

| Reduces Total Dissolved Solids ( TDS ) | Depends on Characteristics of wastewater |

| Increases Dissolved Oxygen ( OD ) | Min 3 – Max 8 |

Preferred Buyer From

| Location | Worldwide |

Product Details

| Available Form | Organic Semi-Solid Form |

| Number of Bacterial Cultures | 45 Different Bacterial Cultures |

| Stage of Bacterial Cultures | Living Bacteria |

| Number of Bacterial Colonies | 24 x 10-9 CFU/ml |

| Shelf Life | Min One Year |

Effluent Parameter Reduction Chart

| Parameters | Percentage of Reduction |

| Sludge Degradation | Zero Sludge |

| Chemical Oxygen Demand ( COD ) | 90 – 98 % |

| Biological Oxygen Demand ( BOD ) | 98 – 100 % |

| Colour | 90 – 100 % |

| Odor | 100% |

| Removal of Suspended & Floatable Organic Debris | 100% |

| Reduces Total Suspended Solids ( TSS ) | 95 – 98 % |

| Reduces Total Dissolved Solids ( TDS ) | Depends on Characteristics of wastewater |

| Increases Dissolved Oxygen ( OD ) | Min 3 – Max 8 |

Preferred Buyer From

| Location | Worldwide |

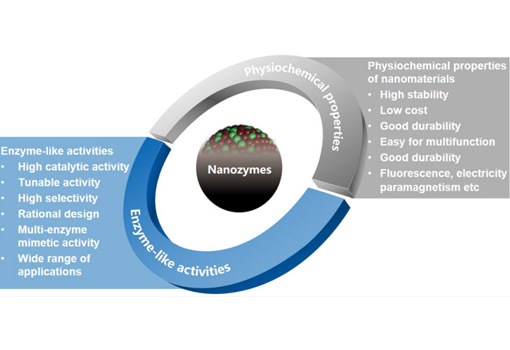

Nanozyme BET-ANA-9003

Business Type : Manufacturer, Exporter, Supplier

MICROBIAL CULTURE / BIO CULTURE FOR PULP AND PAPER INDUSTRIES

Pulp and paper industries generate varieties of complex organic and inorganic pollutants depending upon the type of the pulping process. A state-of-art of treatment processes and efficiencies of various wastewater treatment is presented and critically reviewed in this paper. Process description, source of wastewater and their treatment is discussed in detail. Main emphasis is given to aerobic and anaerobic wastewater treatment.

In pulp and paper mill wastewater treatment aerobic treatment includes activated sludge process, aerated lagoons and aerobic biological reactors. UASB, fluidized bed, anaerobic lagoon and anaerobic contact reactors are the main technologies for anaerobic wastewater treatment. It is found that the combination of anaerobic and aerobic treatment processes is much efficient in the removal of soluble biodegradable organic pollutants. Color can be removed effectively by fungal treatment, coagulation, chemical oxidation, and ozonation. Chlorinated phenolic compounds and adsorable organic halides (AOX) can be efficiently reduced by adsorption, ozonation and membrane filtration techniques.

Product Details

| Available Form | Organic Semi-Solid Form |

| Number of Bacterial Cultures | 45 Different Bacterial Cultures |

| Stage of Bacterial Cultures | Living Bacteria |

| Number of Bacterial Colonies | 28 x 10-9 CFU/ml |

| Shelf Life | Min One Year |

Preferred Buyer From

| Location | Worldwide |

Effluent Parameter Reduction Chart

| Parameters | Percentage of Reduction |

| Sludge Degradation | Zero Sludge |

| Chemical Oxygen Demand ( COD ) | 90 – 98 % |

| Biological Oxygen Demand ( BOD ) | 98 – 100 % |

| Colour | 90 – 100 % |

| Odor | 100 % |

| Removal of Suspended & Floatable Organic Debris | 100 % |

| Reduces Total Suspended Solids ( TSS ) | 95 – 98 % |

| Reduces Total Dissolved Solids ( TDS ) | Depends on Characteristics of wastewater |

| Increases Dissolved Oxygen ( OD ) | Min 3 – Max 8 |