Pulp and paper mill effluent either from thermomechanical pulp mill or chemi-thermomechanical pulp mill is often irrigated to land after primary treatment . Pulp mill effluent has high chemical and biochemical oxygen demand and some wood derived organic compounds, metal(loid)s, fatty and resin acids, and relatively high C:N ratios. Effluent from pulp mills is a rich source of OM, N, P, Ca, Mg, and trace elements and consequently the application of pulp mill effluents on land is becoming a common method for recycling nutrients. The presence of chlorinated organic compounds, most notably chlorine substituted phenolic compounds, chlorinated lignins, dioxins, chlorobenzenes, and non-chlorinated organic compounds, has raised concerns about land application.

The pulp and paper industry consumes enormous amounts of water and natural resources and is also one of the largest effluents generators. Wastewaters from the pulp and paper mills were normally discharged directly to the rivers or lakes, without any treatment or even a rough primary treatment. The high organic loads and solid content in the effluents affected the aquatic ecosystem in several ways such as localized damage to the benthic community, oxygen depletion in large areas and numerous changes in fish reproduction and physiology.

The main concern regarding effluents is the formation of chlorinated compounds in bleaching plants. 2,3,7,8-tetrachlorodibenzo-p-dioxin (TCDD) was discovered in the pulp mill effluents, which led to a general concern over the formation of chlorinated organic matter in chlorine bleaching. Consequently, the use of chlorine in the bleach plants gradually decreased until it was completely substituted with chlorine dioxide. Control authorities set strict restrictions on the discharges of chlorinated organics, measured as adsorbable organic halogen (AOX), into the aquatic environment.

Pulp and paper industrial effluent is rich in recalcitrant compounds and causes pollution. For the treatment of such compounds, an activated sludge process is frequently used.

| Type of waste | Source of waste |

|---|---|

| Black liquor | Chemical pulp manufacture (kraft process) |

| Wood/bark residues [Saw dust and others] | All types of pulping mainly chemical and mechanical methods of pulp manufacturing |

| Screening and other rejects | Stock preparation for paper machine, kraft pulping, and recycling route for paper manufacturing |

| Semi-mechanical sludge | Effluent and water treatment |

| Biological sludge | Effluent treatment utilizing biological technique |

| Sludge from de-inking treatment | Recycled paper de-inking treatment |

| S. N | Main input | Process step | Pollutants |

|---|---|---|---|

| 1 | Raw material/wood | Wood preparation | Solid wastes and wastewater |

| 2 | Chemicals/energy | Pulp manufacture | Air emissions and used water |

| 3 | Process water | Pulp washing/screening | Dissolved material, residual chemicals, and wastewater |

| 4 | Chemicals/energy | Pulp bleaching | Air emissions, dissolved material, residual chemicals, and wastewater |

| 5 | Energy | Pulp drying | Air emissions |

| 6 | Energy/water/chemicals | Paper manufacture | Solid wastes, dissolved material, residual chemicals, and wastewater |

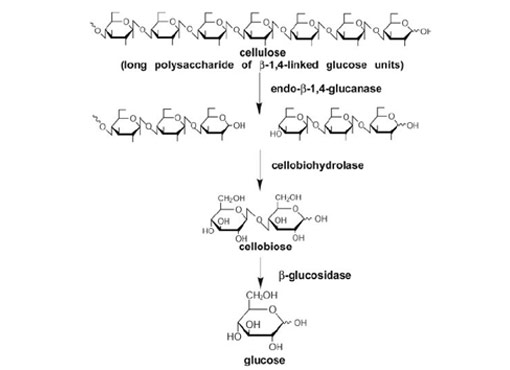

An enzyme is a globular protein with an active site which bind to substrate molecules and helps to catalyse a reaction by holding molecules in the correct spatial conformation for the reaction to take place. The activities of the enzymes are determined by their 3-dimensional structure. Most enzymes are much larger than the substrates they act on and only a small portion of the enzyme around 3-4 aminoacids is directly involved in catalysis.

Nanozyme are based on the latest advanced technology in biotechnology designed to meet the requirements of specific waste water treatment problems. Biological treatment method by Nanozyme microbes is the only method that can eliminate/degrade the waste problem. Specially selected and acclimated strains of microorganisms supplied in NANOZYME microbial enzyme products produce millions of times the levels of organic digesting catalysts produced by various type of microorganisms found naturally in different waste. Bacteria are living organisms that continually adapt and grow in the system.

Nanozyme Effective Microorganism (EM) is the consortia of valuable microorganisms which secretes organic acids and enzymes for utilization and degradation of anthropogenic compounds. Combination of various strains will successively promotes the growth of bacterial population, break down and digest the waste in both aerobic and anaerobic conditions to a far greater degree than single microbial strain. Bioremediation process involves detoxification and mineralization, where the waste is converted into inorganic compounds such as carbon dioxide, water and methane. When compounds are persistent in the environment, their biodegradation often proceeds through multiple steps utilizing different enzyme systems or different microbial populations.

Nanozyme microbial technique for textile dye degradation will be eco-friendly and is probably a lucrative alternative to physio-chemical processes. Nanozyme Microbial enzymes, viz. laccase and azoreductase, are cost-efficient, easily downstream processable, and effortlessly mobilizable. Nanozyme microbial enzyme conjugates are highly efficient to remove the cellulose, starch, lignin from Pulp & paper waste.

The degradation of Pulp & paper effluent by Nanozyme bacteria is facilitated by their oxidases. In the case of Lignin, Cellulose, starch, azoreductase plays the most vital role in decolourization by breaking down azo bonds.

Lignin was considered a typical industrial by-product, available in pulp and paper waste. Lignin is a complex aromatic polymer of high heterogeneity, and is attached to carbohydrate via an ester linkage. It comprises a considerable percentage of lignocellulose (as much as 30%) although it differs according to the type of source.

Lignin includes phenolic compounds, of which there are mainly three groups, i.e., guaiacyl (G), syringyl (S), and hydroxyphenyl (H), which are polymerized via cross-linking mediated by an enzymatic radical reaction, giving rise to β-O-4 bonding dominantly and other C-C and C-O bonding. Because of the intrinsic recalcitrance of lignin, it was simply regarded as waste to be removed from the pre-treated, which is hampered by lignin-derived toxicity.

Lignin degradation occurs in two stages:

The first step in biological lignin valorisation is the decomposition of the lignin polymer. The natural depolymerisation of lignin by Nanozyme, which produce extracellular oxidative enzymes, including laccase and peroxidases. Laccase can oxidize phenolic units with oxygen as an electron acceptor. The laccase from Trametes versicolor was shown to degrade the β-O-4 link within a non-phenolic lignin model. Other enzymes produced by Nanozyme consortia reactive to lignin are heme-containing peroxidases, such as lignin peroxidase (LiP), manganese peroxidase (MnP), and versatile peroxidase (VP).

Nanozyme Bacterial digestion is the process of bacteria, consuming organic & Inorganic matter. Enzymes act to break the organic & Inorganic matter into water soluble nutrients, which the bacteria digest. Using complex chemical reactions, the organic & Inorganic waste is metabolized down to water and carbon dioxide (the final metabolic waste products), providing the bacteria with energy for growth and reproduction. It may be simply shown by the following equation:

Organic waste + Water Soluble Nutrients —–Bacteria + oxygen—> water + carbon dioxide

Organic waste + Water ——Enzyme—-> Water Soluble Nutrients —–Bacteria—> Water + Carbon Dioxide

We are using our product nanozyme in aeration tank capacity which means the ammonical nitrogen totally converted into nitrate nitrogen. It’s an available intake form to our bacteria. So totally we can eliminate the odour and control the ammoniacal nitrogen…. odour is because of ammonical and hydrogen sulphide. No need to remove condensate.

Note that a total ammonia value (NH3 + NH4) cannot be trivially converted from “nitrogen” to “ion” form or vice versa. The total ammonia value must first be broken into component NH3 and NH4 values, then converted individually to NH3-N and NH4-N and added together.

Ammonia removal is a strictly aerobic biological process. Technically, bacteria convert ammonia (NH4 ) to nitrate (NO3 ); it isn’t really “removed.” Nitrification only works on ammonia (NH4 ). Organic-nitrogen is not converted directly to nitrate (NO3 ); it must first be converted to ammonia (NH4 ), and the ammonia (NH4 ) converted to nitrite (NO2 ) and then nitrate (NO3 ).

Organic / Inorganic pollutant load is consumed by the bacteria, used as nutrients by the bacteria, and is no longer present to produce odours, sludge, pollution, or unsightly mess.

The removal of pollutants from the Effluent by using NANOZYME (Effective Microbes (EM)- bacterial consortium manufactured in BIONICS ENVIRO TECH having potential to degrade all organic and inorganic compounds present in the Effluent.

When degradation Organic and inorganic take place which will automatically lead to reduction of COD, When COD takes places which will reflect BOD, Color, smell and etc parameters.

CAPACITY : 6MLD

| S.No | PRODUCT DESCRIPTION | UNIT | Quantity |

|---|---|---|---|

| 1 | NANOZYME BET-ETP-7002 PRO (Pulp & Paper / Kraft) | Kgs | 400 |

| 2 | NANOZYME BET-NUTRI-9003 | Kgs | 200 |

REQUIRED MATERIALS FOR PREPARATION:

NANOZYME INCUBATION METHOD:

| Dosage | Day of Dosage | From 10000 litres of prepared broth Volume of Nanozyme Application to Aeration | |

|---|---|---|---|

| 1st Dosage | 1st to 10 days | 300 Litres / Day | |

| 2nd Dosage | 11th to 20th Days | 300 Litres / Day | |

| 3rd Dosage | 21st to 30th Days | 300 Litres / Day |

DOSAGE LOCATION OF NANOZYME CULTURE: AERATION TANK

| S.no | Product Description | Unit | Qty | Unit Price in INR |

|---|---|---|---|---|

| 1 | NANOZYME BET-ANA-9002 | Kgs | 400 | 1200 |

| 2 | NANOZYME BET-NUTRI-9003 | Kgs | 200 | 300 |